How 3D Printing with Conformal Cooling Cut Injection Mould Cycle Times by 35%

In high-volume manufacturing, especially in the automotive world, every second saved on the production line makes a difference. For one parts supplier, the biggest bottleneck wasn’t the injection moulding machine or the material, it was the mould cooling.

Traditionally, cooling channels in injection moulds are drilled in straight lines. It’s simple but not ideal. These channels often end up too far from the actual mould surface, especially in complex parts. That means heat isn’t pulled away efficiently, which causes warping, dimensional inaccuracies, longer cycle times, and higher defect rates. In this case, 60% of the entire injection cycle, 88 seconds, was just cooling.

That’s where metal Additive Manufacturing came in. With help from ZRapid’s iSLM280 Selective Laser Melting (SLM) system, a manufacturer completely redesigned the cooling approach. The key was conformal cooling channels: curved paths that follow the shape of the mould and stay close to heat-sensitive zones.

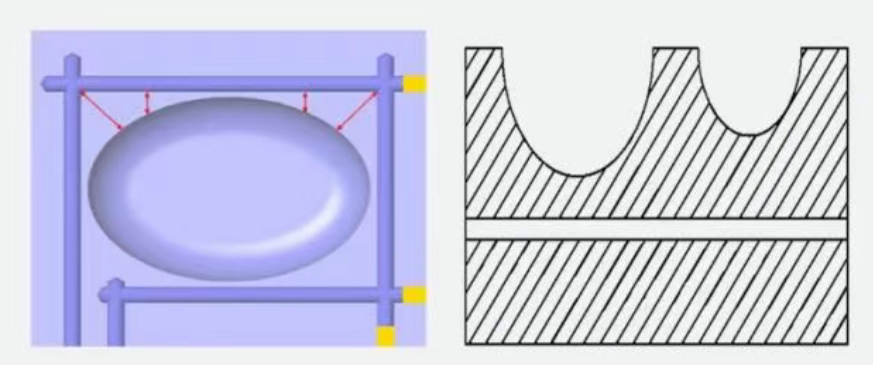

What’s Wrong with Straight Cooling Channels?

Straight-line cooling has a few big limitations:

◾ The channels can’t follow curved mould surfaces.

◾ They’re usually 8 to 10 millimeters away from where heat actually builds up.

◾ Sharp turns and intersections slow down coolant flow.

◾ Assembling moulds with straight channels often means putting together multiple metal pieces, which leads to leaks, wear, and alignment issues.

The result is uneven cooling. And in injection moulding, uneven cooling is often the root cause of problems like warping, sink marks, and longer solidification times.

Straight-line cooling channels

Conformal Cooling

For this manufacturer, those issues translated into a 5-6% defect rate, an 88-second cooling phase, high material waste during mould production, and shorter mould lifespans due to wear and misalignment.

What Conformal Cooling Solves

With 3D printing, especially using SLM, it’s possible to build internal cooling channels that curve and twist in ways traditional machining can’t. These channels can stay consistently 2 to 3 millimeters from the mould surface, making them much more effective at pulling heat away right where it matters. That closeness improves heat transfer. The temperature drops faster when the contact is closer, and the same principle applies here.

Also, the smoother shapes of conformal channels improve coolant flow. There’s less turbulence, fewer dead zones, and more efficient cooling. That helps maintain uniform temperatures throughout the mould, preventing hot spots and reducing defects.

The ZRapid Solution

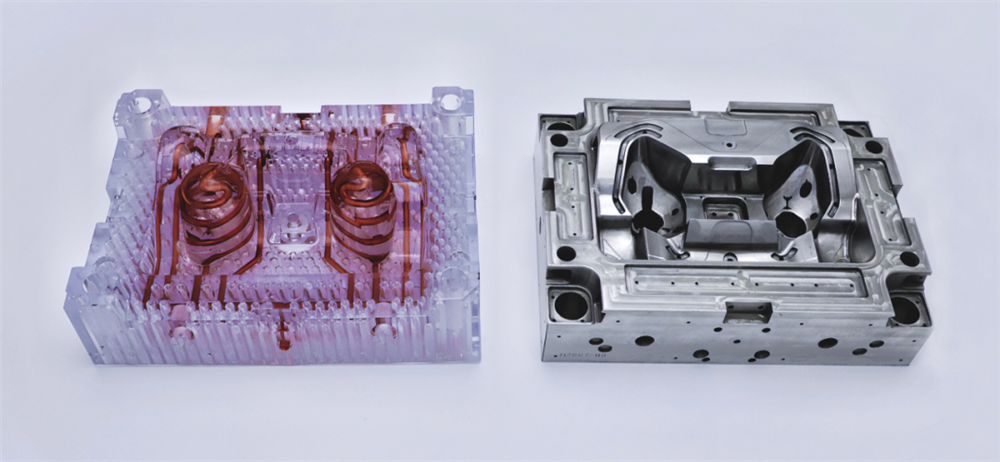

ZRapid used their iSLM280 metal 3D printer to help the manufacturer redesign two key mould components.

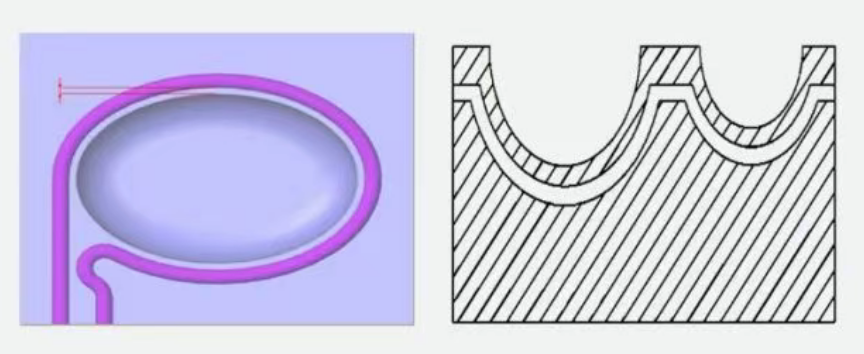

1. Conformal Cooling Insert

◾ Material: 18Ni300 maraging steel

◾ Print time: 6.5 hours

◾ Channel distance: 2 to 3 millimeters from mould surface

◾ Channel diameter: 16 millimeters

◾ Layer thickness: 0.035 millimeters

This insert was used to cool hard-to-reach zones in the mould, where conventional drilling methods couldn’t provide efficient cooling.

2. Full Mould Core with Integrated Cooling

◾ Material: CX tool steel

◾ Print time: 45 hours

◾ Layer thickness: 0.04 millimeters

◾ Design: Multi-loop cooling channels built into a single printed component

This replaced a traditional multi-piece core with a single part, eliminating joints, gaps, and sealing problems.

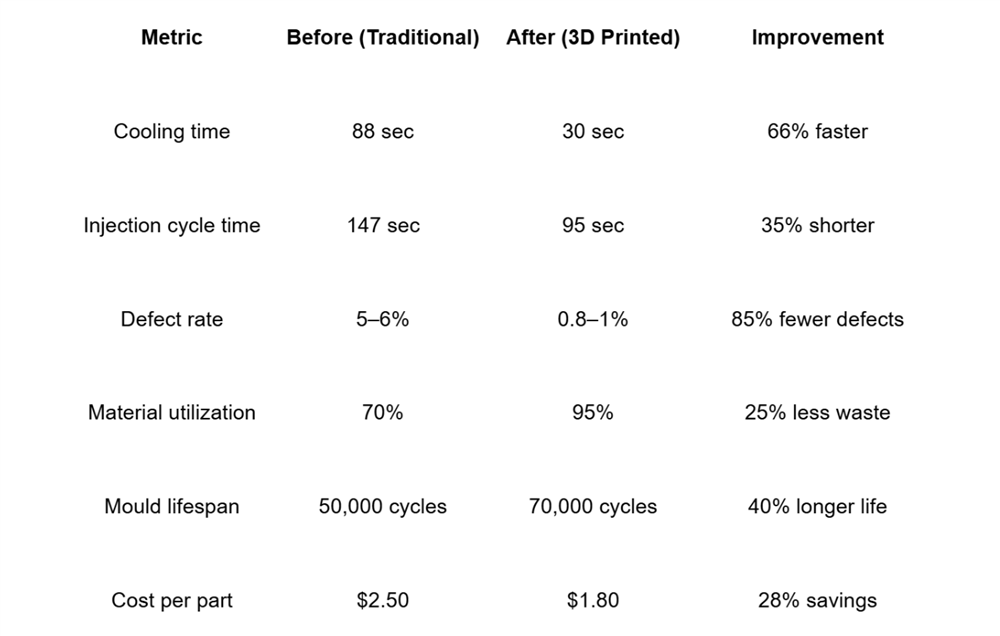

Results That Speak for Themselves

After switching to 3D-printed conformal cooling, the improvements were significant:

This level of improvement adds up quickly in a production environment. Faster cycles and fewer defects directly translate to higher output and lower cost per unit.

Why the Material Choice Mattered

Choosing the right tool steel for the job was critical. These materials had to handle repeated thermal cycling, high pressures, and mechanical wear.

18Ni300 (Maraging Steel)

◾ High strength and hardness after aging

◾ Good dimensional stability

◾ Thermal conductivity around 25 W/m·K

◾ Ideal for detailed inserts with fine cooling channels

CX Tool Steel

◾ Higher wear resistance and improved toughness

◾ Better thermal shock resistance

◾Suitable for larger, full-core components exposed to high stress and heat

Both materials responded well to additive manufacturing and post-processing steps, including heat treatment and finishing.

Post-Processing and Validation

Even with precision 3D printing, post-processing is essential:

◾ Heat treatment relieves internal stresses and enhances strength.

◾ Machining and polishing ensure tight tolerances and clean surfaces.

◾ CFD simulations help test and validate cooling designs before printing.

◾ Thermal imaging and in-mould sensors confirm real-world performance during testing.

These steps guarantee that the mould isn’t just innovative in theory but also reliable in production.

What This Means for the Future of Mould Making

This case proves that additive manufacturing is ready for production tooling. By shifting from traditional thinking to design for additive manufacturing (DfAM), manufacturers can create:

◾ Faster-cooling moulds

◾ More consistent part quality

◾ Longer-lasting tools

◾ Lower production costs

And this isn’t limited to automotive. Other industries such as day-to-day parts, medical devices, and consumer products are also starting to adopt conformal cooling strategies.

While SLM systems have a higher upfront cost than conventional methods, the long-term benefits make them a smart investment for companies focused on efficiency and scale.

What ZRapid achieved here wasn’t just a technical upgrade. It was a major leap in how moulds are designed and built. By combining smart materials, conformal cooling, and high-resolution 3D printing, they helped a manufacturer cut cycle times, reduce waste, and produce better parts at a lower cost.

Additive manufacturing is no longer just for prototypes. With the right design, tools, and engineering mindset, it’s becoming a go-to solution for solving real manufacturing challenges.

Contact us, and our expert team will help you find the best solution tailored to your needs!

Email: info@anima.eu

Contact number: +30 210 77 76 822