Re-Engineering a Pneumatic Cylinder Hinge Point Through Metal Additive Manufacturing

Introduction

In industrial machine design, many of the components that have the greatest influence on process reliability are not the most complex ones. Often, performance depends on small functional parts that define movement, alignment, or load transfer within an assembly. When these parts have non-standard geometries or need to be adjusted repeatedly during development, traditional fabrication methods can become restrictive. This was the situation faced by Handsaeme Machinery while optimizing a hinge point for a pneumatic cylinder in one of their carpet rolling machines. The hinge controls the cylinder’s movement path, which in turn controls how tightly and consistently the carpet roll is formed.

Handsaeme has been integrating additive manufacturing into their workflow for several years. Their internal operations include prototypes and trial parts produced on ZRapid Europe SLM systems supplied by ANiMA. The hinge point project represents a typical case where metal additive manufacturing provides a clear engineering advantage. The goal was not to showcase a novel concept, but to refine a practical component that must perform reliably under repetitive motion and specific directional loads.

This case study explains the problem Handsaeme needed to solve, the limitations of their conventional welded assembly, and the reasoning behind transitioning to SLM. It also provides an overview of how the redesign improved accuracy, reduced iteration time, and simplified the production sequence.

Engineering Requirements and Functional Constraints

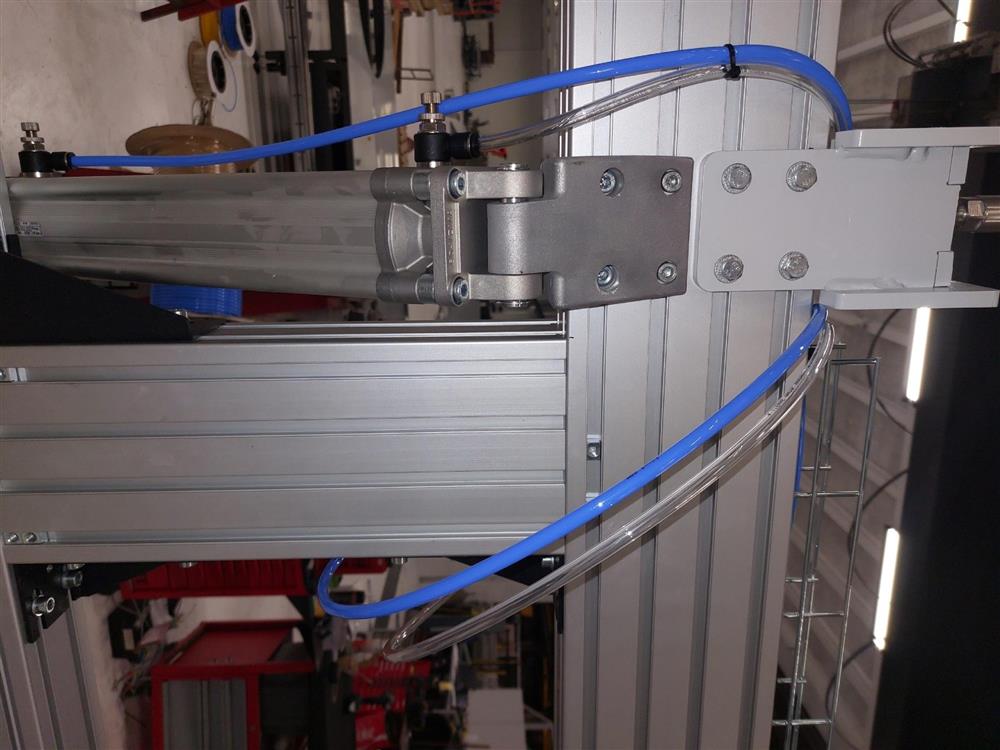

The hinge point functions as the connection between the carpet rolling mechanism and the pneumatic cylinder that drives it. For the machine to operate correctly, the cylinder must follow a defined movement path that ensures controlled tension on the carpet as it is rolled. Any deviation in this path changes the pressure distribution across the roll. This can cause inconsistent winding or increased need for operator intervention. Because the hinge angle determines the initial alignment of the cylinder, the part must be manufactured with high geometric accuracy and repeatability.

In the existing configuration, the hinge point was fabricated using several laser-cut steel plates that were welded together. This approach works well for standard hinge geometries, but it becomes more restrictive as soon as a specific non-standard angle is required. Each plate brings its own dimensional tolerance from cutting, and each weld introduces local distortion. Even when welds are well executed, small variations accumulate and influence the final angle. For a part that directly controls motion, this variability resulted in additional alignment steps during assembly and increased development time whenever adjustments were needed.

Handsaeme also needed a way to iterate the geometry efficiently. Their engineers were fine-tuning the angle to achieve consistent, tightly wound rolls under different operating conditions. With welded assemblies, modifying the angle means preparing a new set of laser-cut plates and repeating the welding sequence. This takes time and makes quick iterations difficult. For a team that designs multiple customized machines each year, this delay becomes a limiting factor. A more flexible and digitally controlled production process was necessary to achieve the required precision and support ongoing design changes.

Transitioning From Welded Fabrication to SLM Manufacturing

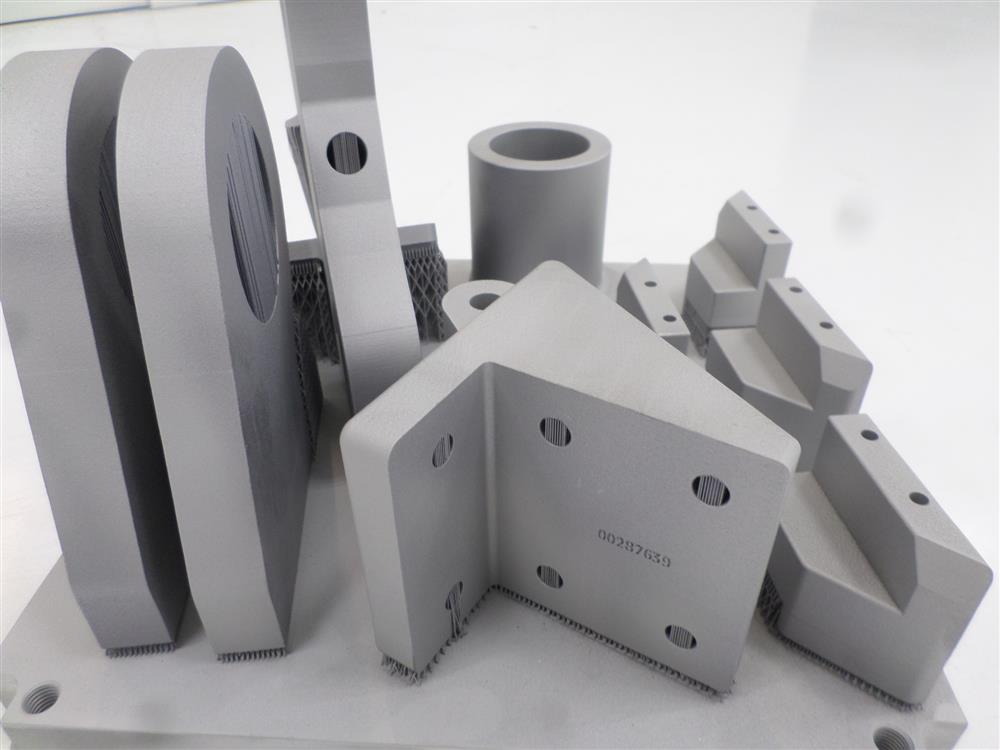

Selective laser melting allowed the hinge point to be produced as a single metal component. Instead of relying on multiple cut plates positioned manually during welding, the geometry is defined entirely in the CAD model. The printed part comes out of the machine with the intended shape and no assembly seams. This eliminates tolerance stack up and removes unpredictable distortions. For a geometry where the angle is the main functional element, being able to manufacture the part in one piece significantly improves accuracy.

The digital workflow also changed the speed of iteration. Once Handsaeme determined that a new angle or a small design adjustment was required, they could update the build preparation and produce a new metal part overnight. This reduces the iteration cycle from several days to a single working day. It also allows engineers to test incremental improvements without the overhead of preparing and welding new plate assemblies. With SLM, the only variation between iterations is the geometry in the CAD file. This consistency makes it easier to evaluate the effect of each design change.

The new workflow followed a straightforward sequence. Handsaeme finalized the hinge geometry digitally after preliminary checks and fit tests. Then prepared the build, produced the part using an SLM system, performed the required post-processing, and delivered the final component ready for installation. Because the hinge is printed as a monolithic part, no painting or welding cleanup was required. The end result is a component that integrates directly into the machine with minimal additional handling. This combination of speed, accuracy, and reduced manual work reflects the practical value of metal AM in mechanical engineering tasks like this one.

Technical Outcomes and Operational Impact

The SLM hinge point met the functional requirements while eliminating several constraints of the traditional welded version. The printed component provided the exact angle required for the pneumatic cylinder’s motion path, allowing the rolling mechanism to maintain consistent tension throughout the cycle. By removing welds and manual alignment steps, Handsaeme achieved a more predictable and stable geometry. This consistency is critical for a component that influences repetitive motion and mechanical timing.

The production process also became more compact. There is no need for laser cutting, welding, painting, or assembly of multiple plates. This reduces labour time and simplifies scheduling. While the cost of an SLM part must be evaluated on a case-by-case basis, the reduction in intermediate steps and rework often offsets part of the unit cost, especially when iterative development or non-standard geometry is involved. The benefits are even more visible in cases where several custom hinge points are required for different machine configurations, since repeatability is higher and the lead time is more predictable.

Beyond the specific hinge application, the project illustrates how Handsaeme integrates metal additive manufacturing into their development and production workflow. Not every part is suited for SLM; however, for components where geometry accuracy, monolithic structure, and fast iteration are important, SLM provides a practical and reliable solution.

Contact us, and our expert team will help you find the best solution tailored to your needs!

Email: info@anima.eu

Contact number: +30 210 77 76 822